| Frequency : | 860-960MHz; 13.56MHz; 125KHz/134.2KHz | Application : | Textile rental & Dry cleaning / Track & Manage Inventory / Logistic Tracking |

| chip : | Customized. | Special Features : | Waterproof, moisture resistant, corrosion resistant |

| Working Temperature | -20~180°C / 20%-90% RH | Place of Origin : | China,GuangZhou |

| Brand Name : | ZF PPS Tags | Product name : | RFID PPS Tags |

| Size : | Customized | Material : | PPS |

| Printing : | Offset Printing | Color : | Customized Color |

| Communication Type : | RFID | Craft : | Laser Code / QR Code |

| Surface : | PPS | Customized support : | Customized logo, Graphic customization |

Material Advantages:

Application scenarios:

|

|||

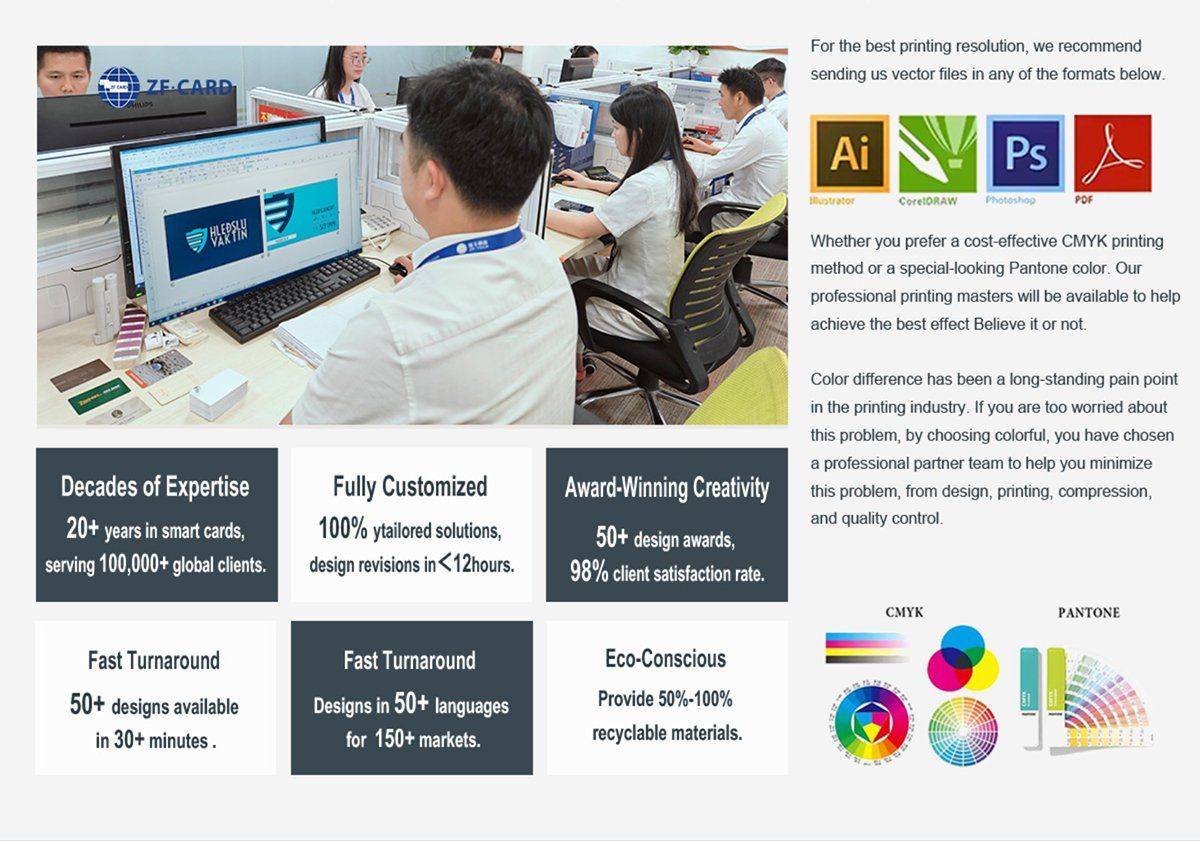

| Our Featured Services | |||

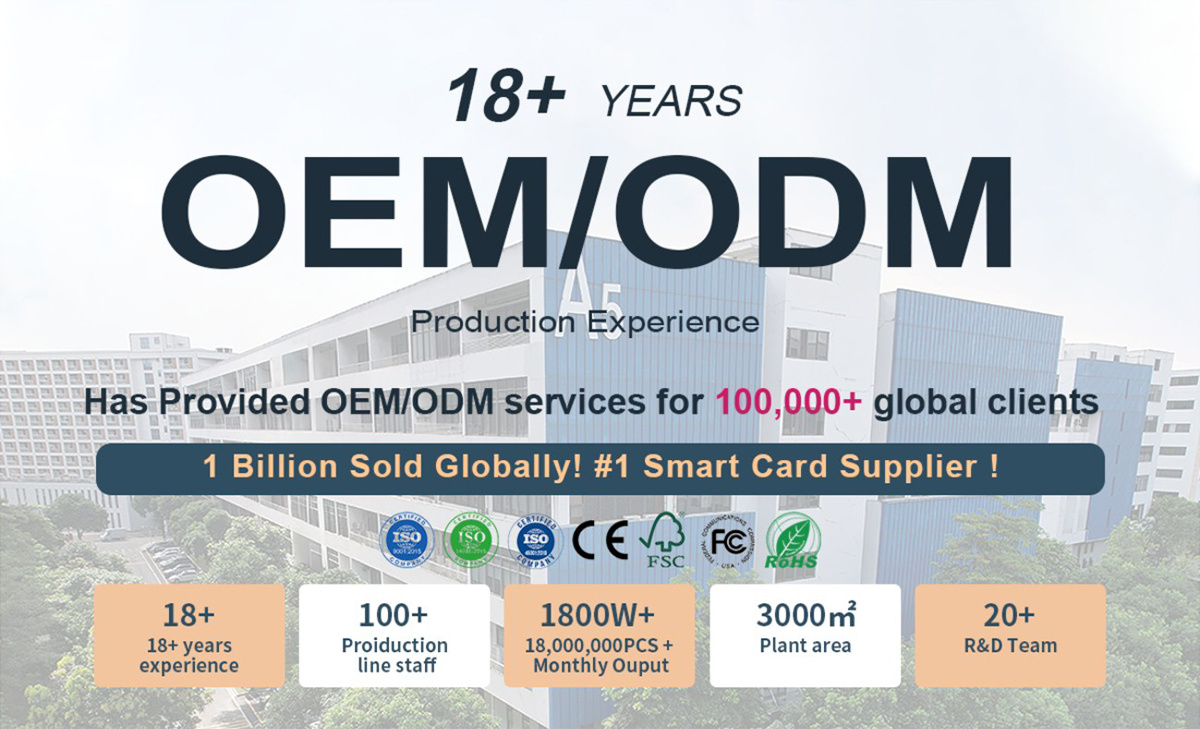

| 1. All our products are made with private molds and have patents, which can protect your brand and authorize you to have exclusive regional sales rights. 2. We have a 20+ R&D team, services for your brands (incl. customization on mold design, color, logo, label, packaging, and more...).please contact our for more detail. 3. Support small order customization: No matter how big or small your order is, we attach the same importance to it and accompany our customers to grow with the same high-quality service. So, contact us now and we will do our best price and quality service for you! |

|||